Recorded September 30th, 2021

Part 1 can be found here: https://mkt.3dcs.com/new-version-3dcs-7-8-collision-detection-gear-module

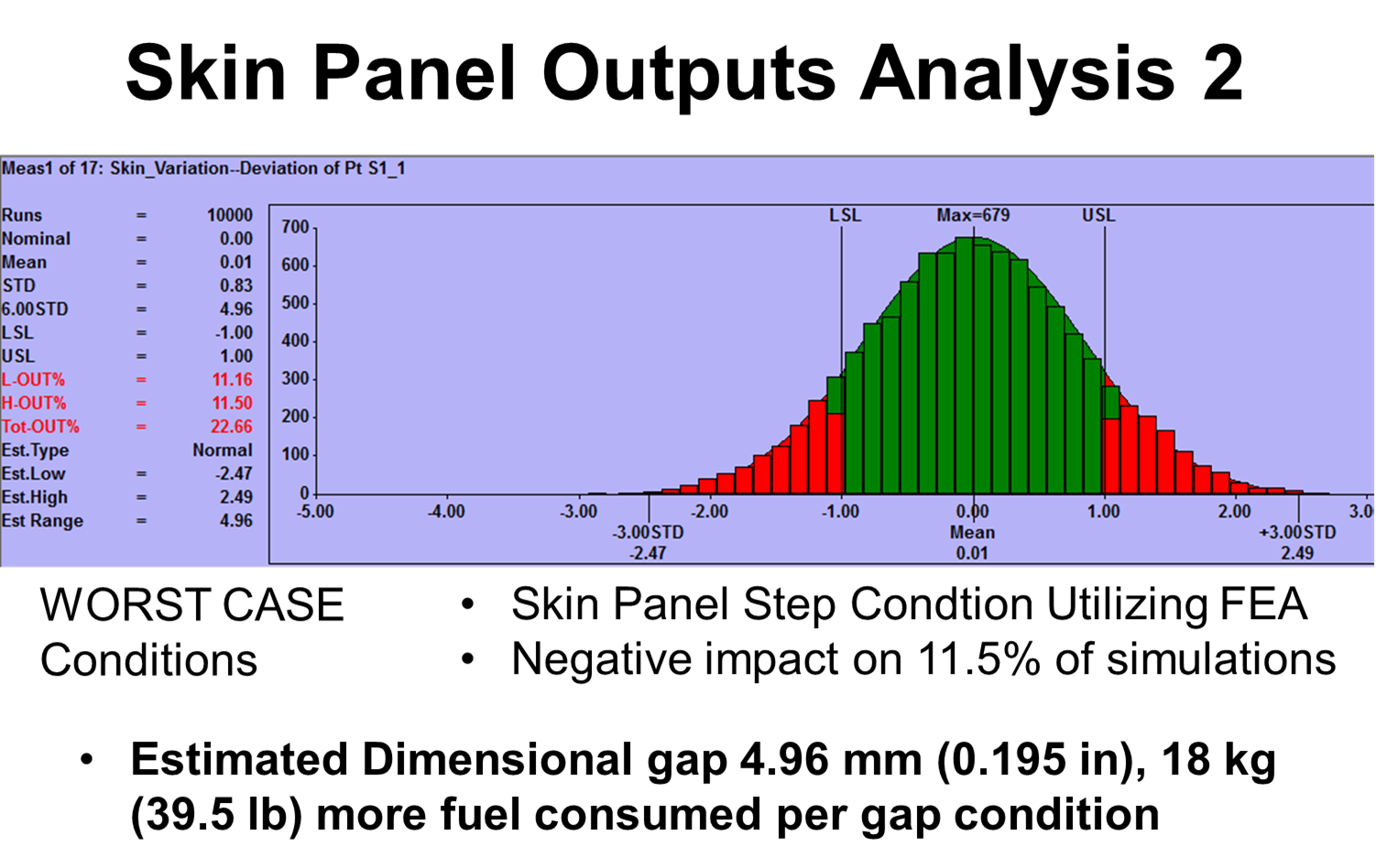

3DCS has been updated with more options for your worst-case analysis. These tolerance stack-ups set the values at their greatest values, showing the largest range of variation possible. Additionally, there are worst-case scenarios that cause the greatest amount of risk and product failure which may not be from setting all values to their largest amount.

Learn about the options within 3DCS to perform a Worst Case study including:

--GeoFactor and BiModal Analysis

--Statistical vs. Worst Case Results

--The impact of Bonus (LMC/MMC) and Datum Shift (MMB/LMB) on a Worst --Case study

--3D effects for a Worst Case analysis

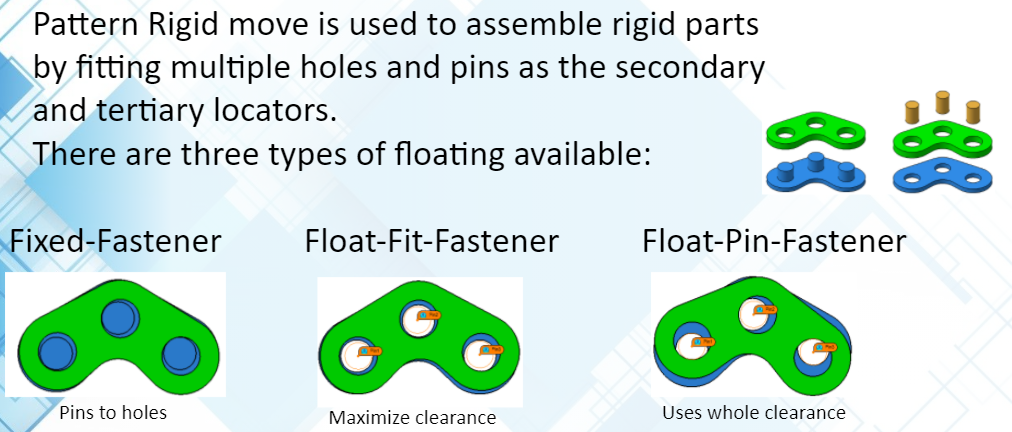

The Pattern Move is an important tool for any engineer using 3DCS. This assembly process allows you to simulate patterns of holes and pins, and see how they align and fit with your given tolerance specifications. This can help you understand whether parts will fit in assembly, or require adjustments to specific holes, or changes to slots in order to assemble correctly without the need to enlarge holes or alter the parts.

New features in the Rigid Pattern move include the ability to float slots onto pins and tabs. This is what is covered in this presentation:

--New Features

--Float-Hole-Slot-Pin Pattern