Simulation provides examples of possible outcomes in production, allowing users to determine their risk of failure. However, the ability to use measured data from manufacturing turns simulation from a predictive tool into a powerful root cause analysis and validation tool.

In this webinar, learn how to automate the use of measurement data in 3DCS Variation Analyst to run tests, simulations, analyses, and root-cause analyses on your manufacturing quality. Utilize your CAD points with your CMM to easily correlate the data and unlock the power of 3DCS software for your as-built products.

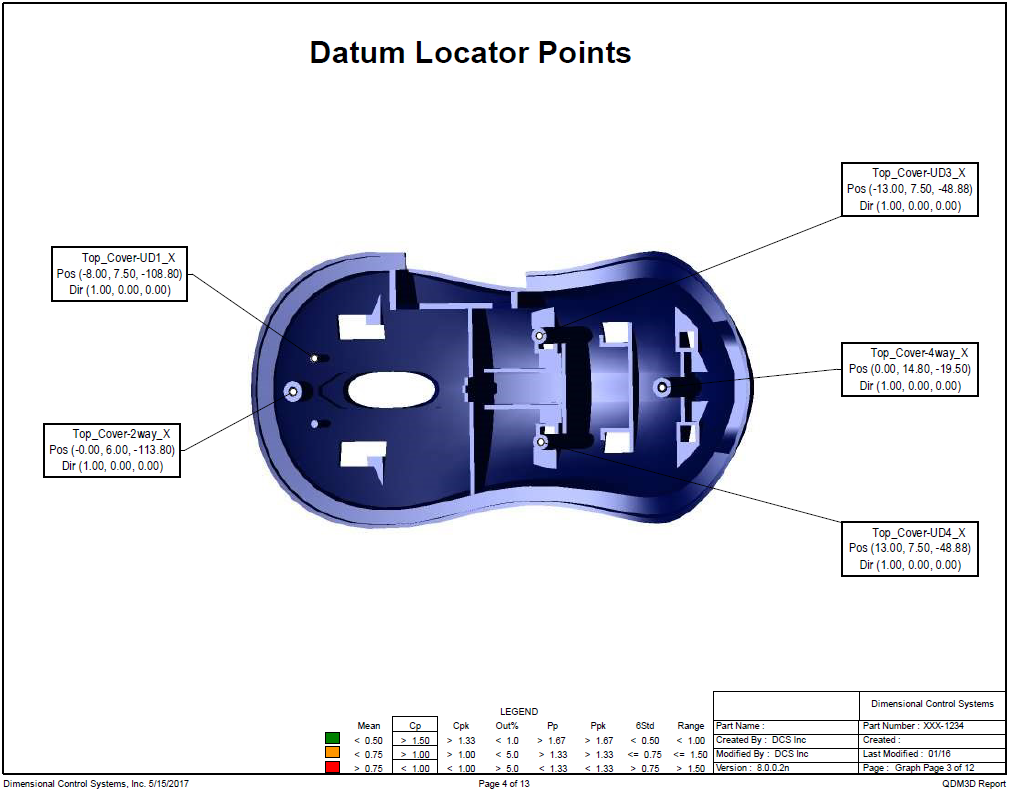

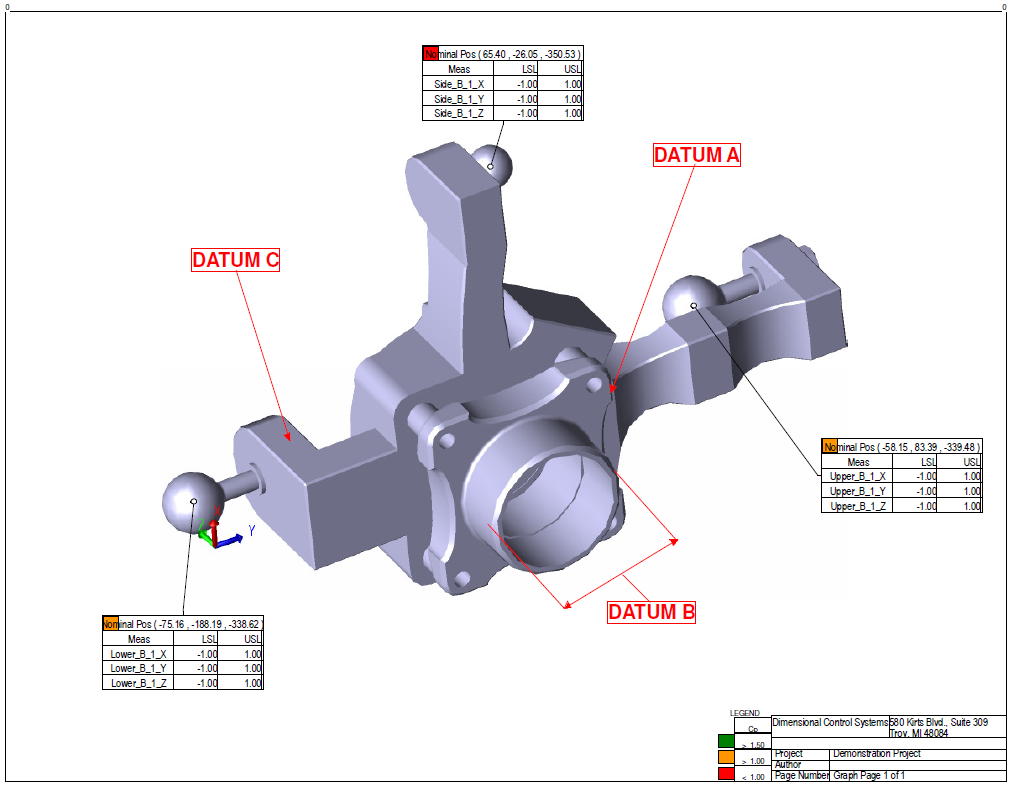

3DCS Variation Analyst is a CAD-based simulation software that determines the risk of failure in production and the amount of variation expected from a given design when manufactured. Using Monte Carlo Analysis to simulate the Digital Twin, 3DCS provides the most advanced tolerance analysis tool on the market.

3DCS Variation Analyst offers users the ability to do more than just 3D stack-ups by analyzing the relationship between your parts and accounting for a multitude of sources of variation. This gives you the most accurate results to make important decisions about your design and manufacturing processes.