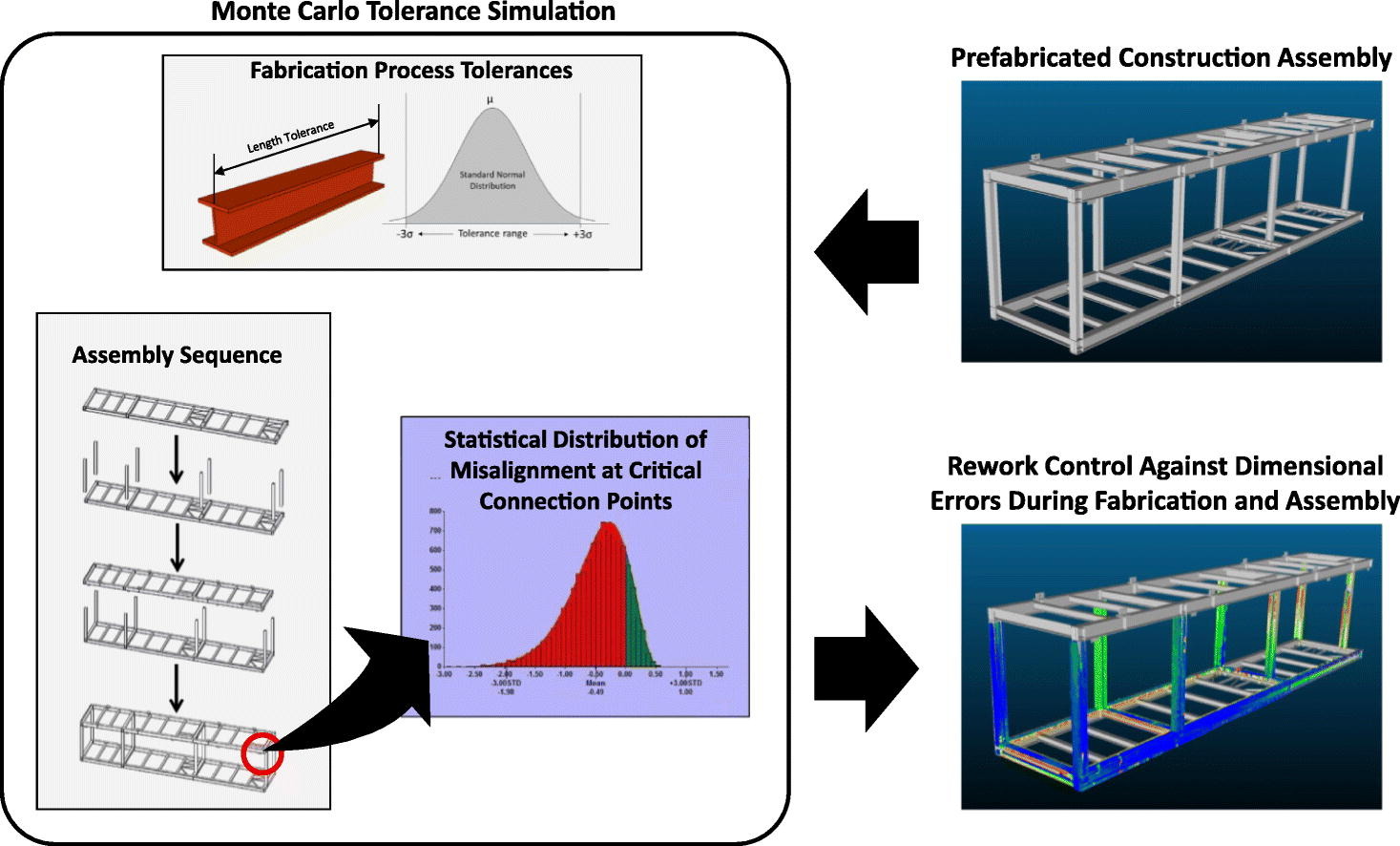

Producing assemblies that experience little to no rework during assembly fit-up is a perennial challenge in offsite construction. While the traditional response has been to solve geometric issues onsite at the expense of large rework costs, manufacturing optimization techniques can mitigate these issues upstream. Tolerance analysis is one such method that is widely used in manufacturing to predict if problems will occur from the accumulation of tolerances and dimensional variability.

This article demonstrates Monte Carlo tolerance simulation on a prefabricated construction assembly, where variations up to 37 mm are identified compared to as-built deviations which range up to 30 mm. Process optimisation is also explored, where risk of rework related to dimensional variability is reduced by 65.6% through selection of alternate fabrication processes.

To compare the Monte Carlo method to traditional analysis methods, a simplified 1-D tolerance analysis is used. Compared to an as-built deviation of roughly 11 mm, the Monte Carlo method produces a conservative value of 15.4 mm, while other traditional methods are either overly conservative (worst-case tolerance chain has a deviation of 19.8 mm), or overly ambitious (root sum square tolerance chain has a deviation of 4.6 mm).

Tolerance analysis through Monte Carlo simulation is shown to be a proactive design tool with several key advantages for prefabricated and offsite construction.

1. First, complex three-dimensional geometric interactions can be readily modeled using very basic tolerance configurations.

2. Secondly, potential misalignments at key connection points can be identified and quantified in terms of a probability distribution of variation.

3. Finally, design improvements can be achieved by comparing alternate construction processes to mitigate the risk of assembly rework.