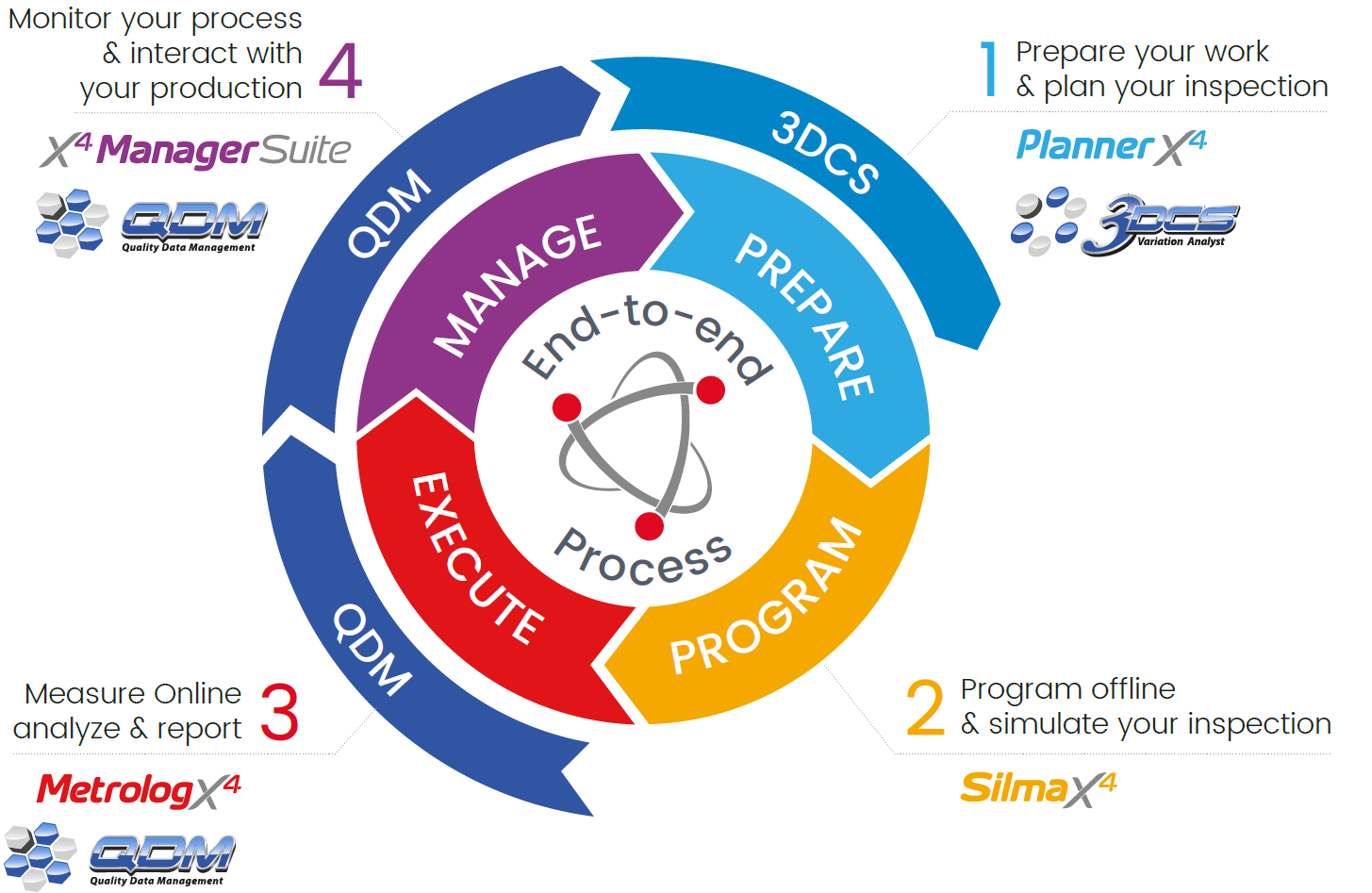

From creating and optimizing GD&T during the digital phase through simulation, to inspection planning, device programming, and data collection, all the way to high-level SPC analytics, real-time monitoring, and dashboard, the end-to-end solution streamlines your quality throughout the product lifecycle.

Keep an eye on our blog, and join us at the event to learn more about how you can take advantage of the end-to-end solution in part, or in whole, to automate your quality processes and reduce your costs.

There is always an easier way to do things, whether we know it or not. Let the experts at DCS help you find an easier way to manufacture by leveraging the Digital Twin and manufacturing automation to reduce your costs while improving quality at the same time.

Quality is important. Getting real results and improvement from your quality processes is not easy, though. Collecting data and measurements is only the first step, as making actionable decisions from that data can take many hours of diving through large datasets, looking at huge spreadsheets, and crunching statistics.

Find out from DCS Six Sigma Black Belts how you can automate your quality processes to get from measuring to actionable Quality Intelligence - the information you need to make decisions about your quality and manufacturing.

Get expert advice from Six Sigma Black Belts and spend more time solving problems, and less time crunching numbers.