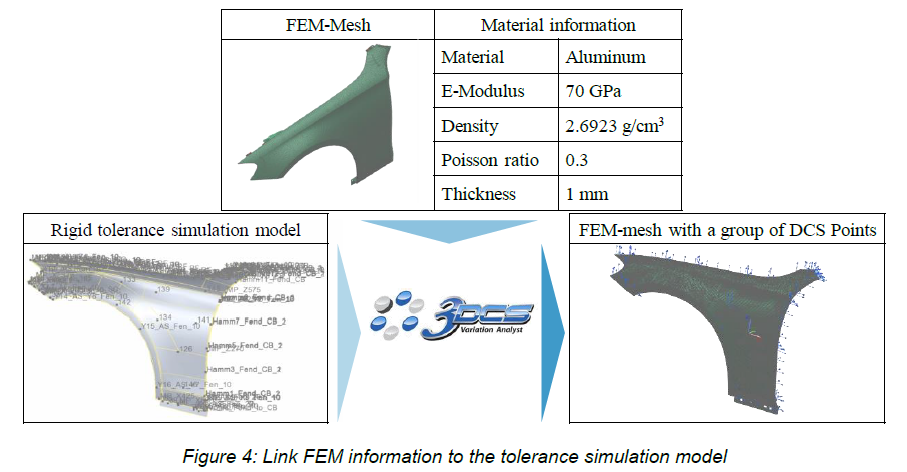

Computer-aided tolerancing (CAT) in the automobile industry is implemented by CAD tools. These tools analyze the manufacturability of complex assemblies with rigid single parts in an early stage to reduce the product development time and the cost for hardware prototypes. This paper proposes an approach to implement tolerance simulation for a compliant assembly, which includes manufacturing processes such as clinching, bolting, and hemming by applying tolerance simulation tool.

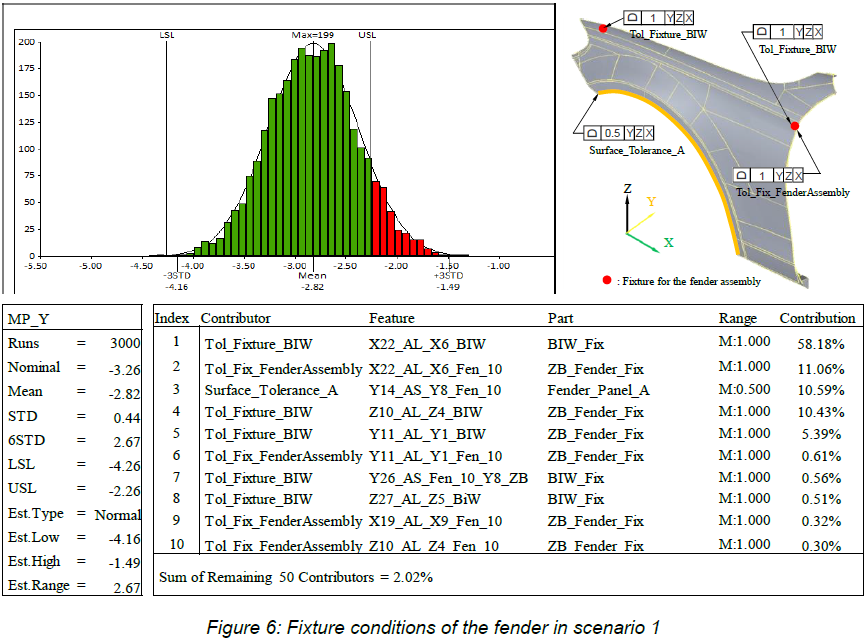

The fender-BIW system is simulated as a compliant–rigid system and the simulation model is applied to two production scenarios. The simulation results are compared with real measurement data, which demonstrates the efficacy of using simulation in early production as opposed to prototyping or other methods of design by showing the strong correlation between simulation results and as-built products.

Contents:

DCS will never share your information with a third party or add you to a mailing list without permission. Read our privacy policy to learn more about how DCS protects your information.