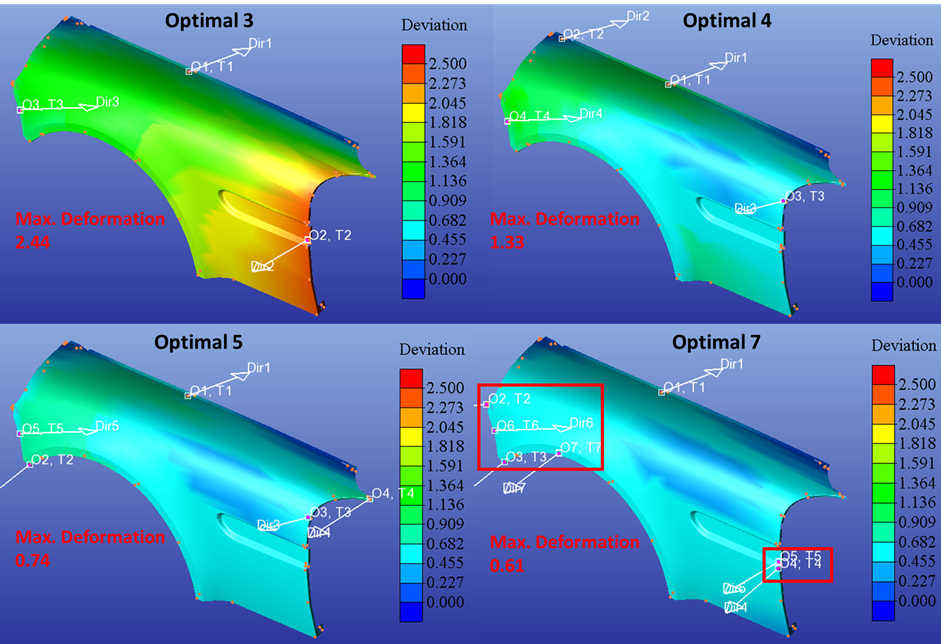

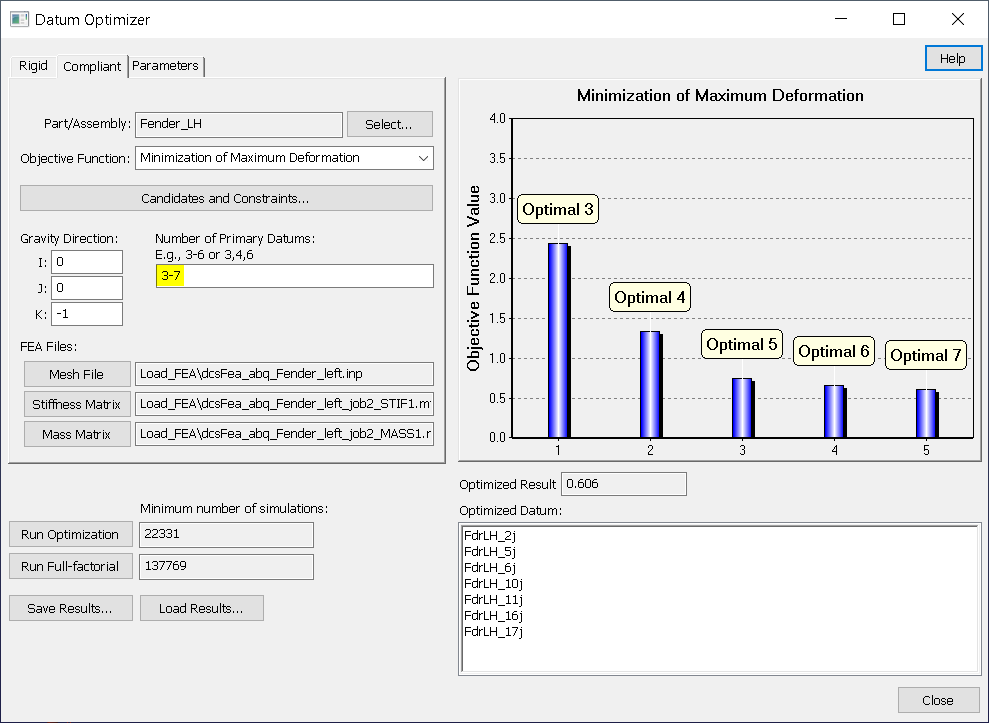

3DCS Datum Optimizer (DO) is a tool that uses a genetic algorithm (GA) to determine the optimal datum features from a candidate set with the goal of minimizing the rigid part variation or compliant part deformation. Using DO during the design stage and prior to production gives users the ability to eliminate or minimize rework, reduce tuning mechanisms to select the proper datum features, and have a higher confidence in passing Gage Repeatability and Reproducibility (R&R) studies.

Improper selection of datum features during manufacturing and assembly may cause severe quality problems. Improper datum features risk turning all the quality parts, accurate dimensioning and tolerancing, and first-class operations into a defective assembly.

Datum Optimizer is an easy-to-use tool in 3DCS Advanced Analyzer and Optimizer Add-on, which does not require creating moves (Assembly Definition) or tolerances on the model. For a rigid part, it only requires a single CAD part with a set of candidate points. For a compliant part, besides the part and candidate points, it additionally requires the 3DCS FEA Compliant Modeler Add-on and Finite Element Analysis (FEA) files to be ready as it involves FEA calculations.

This white paper discusses the background of Datum Optimizer in the following section. Two functionalities of DO are described in the third section, followed by a brief description of the genetic algorithm. To illustrate the process, an example model is included in the fourth section. Finally, the results are discussed in the conclusion as well as further planned development.

DCS will never share your information with a third party or add you to a mailing list without permission. Read our privacy policy to learn more about how DCS protects your information.